塑料

EFFICIENCY AND PERFORMANCE CONSTANCY WITH THE NEW FLOW MAX DRYING SYSTEM

2010-5-4 來源:中國聚合物網

關鍵詞:PET drying systems MORETTO

2010-5-4 來源:中國聚合物網

關鍵詞:PET drying systems MORETTO

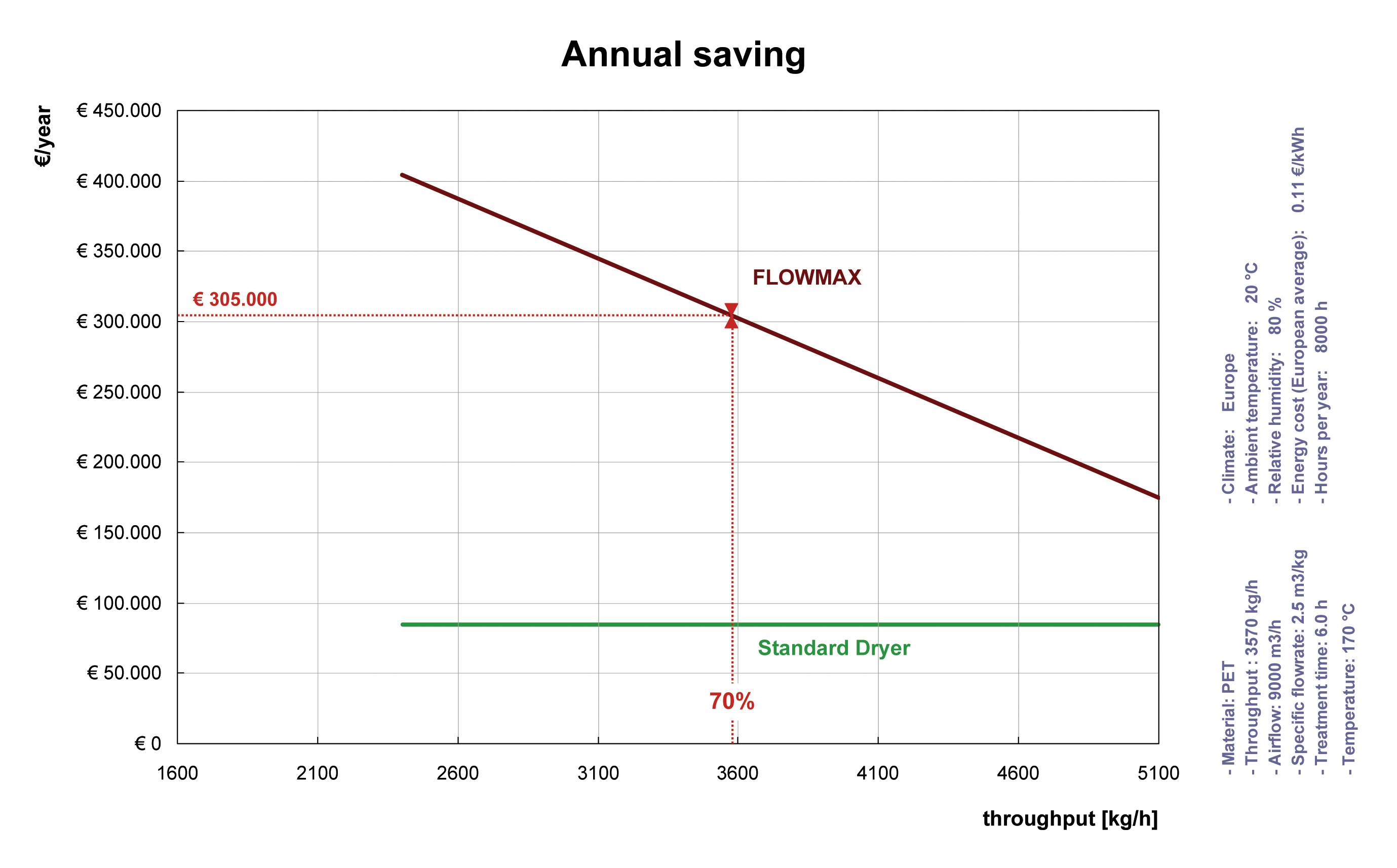

Figure 5

The FLOWMAX system can have different configurations according to the individual requirements: the combinations Flowmatik Uni, Twin and Multi with the X MAX dryers creates complete Uni and multi-hopper systems which are able to meet a wide range of needs in the feeding and drying with very low energy consumption. Besides, they don’t require compressed air and cooling water.

FLOWMAX UNI is composed by a battery of X MAX units with a single hopper suitable for the throughput to be done. It is used for the dehumidification of big quantities of plastics, up to 10,000-12,000 kg/h.

In the treatment of numerous materials, X MAX combines perfectly with Flowmatik, realizing the Flowmatik Multi configuration and realizing an efficient and functional system able to satisfy big production needs.

For the realization of centralized systems, the configuration FLOWMAX PET System permits to have a complete system guaranteeing process constancy, simple management and a drastic reduction of the PET treatment cost.

In case of particularly narrow spaces, instead of the battery of X MAX dryers, MORETTO can develop PET systems where a dryer is installed on board each single hopper on the IMM. Apart from the space, the systems are supplied together with the MOWIS centralized supervision system.

The operation of these high airflow drying systems is very simple; the operator sets only two parameters on a user-friendly touch screen interface: the type of material and the throughput. Then the system activates automatically with the selection of the exact quantity of process air. This allows to get an optimized drying and feeding to one or more IMM which produce PET preforms for the following blow moulding which transforms the preforms into bottles.

This new system is marked with the “Green Factor” label, considering the particularly low energy consumption. This comes from the results of the tests made comparing the system based on FLOWMAX and a conventional system for the PET drying.

Figure 6

The conventional systems at present on the market have a maximum dimension of about 4,000 m³/h and generate a throughput of up to 1,300 kg/h. This corresponds to the production of an IMM with 144 cavities, so a drying system with a maximum capacity dedicated to a single IMM. FLOWMAX can reach up to 8,000 kg/h of PET with a modular generator of 20,000 m³/h. A modular system of big dimensions is much more advantageous compared to individual systems which have more working components and imply a higher risk of failures of the components.

Besides, FLOWMAX has particular circuits that allow to recover the total energy used in the system and to process every Watt in the polymer treatment. Thanks to this exclusive characteristic, the investment return is guaranteed in only 2 years considering only the reduction of the energy cost. Considering this exceptional advantage and assuming that this investment is projected at least in the next 10 years, from the third year it is on profit. The containment of the energy costs in 8 years allows a savings such as to present a new IMM. MORETTO has simulated a battery of 5 machines with 72 cavities with a production of about 3,600 kg/h and has calculated the cost with reference to the drying. The tests have been realized in European condition – temperature 20° C, relative moisture of 80% and based on 6 hours of treatment at 180° C with a specific airflow of 2.5 m³/kg on 8,500 hours/year of production.

The following graph shows how the cost of the equipment is not important, while a strategic role is covered by the energy cost which represents the 90% of the total costs in 10 years of use.

注:本網轉載內容均注明出處,轉載是出于傳遞更多信息之目的,并不意味著贊同其觀點或證實其內容的真實性。

(藍劍)

- 相關新聞

- 無相關新聞