17. Polypropylene composites with ultrahigh low-temperature toughness by tuning the phase morphology

writer:Zhong-Guo Zhao, Sheng-Tai Zhou, Li-Jun Quan, Wei-Long Xia, Qian Fan, Peng-Hui Zhang, Yan-Hui Chen*,

keywords:Isotactic polypropylene, Carbon nanotubes, Ethylene-octene multiblock copolymer,Low-temperature toughness,Co-continuous phase morphology

source:期刊

specific source:Industrial & Engineering Chemistry Research, 2022, 61, 41, 15240-15248.

Issue time:2022年

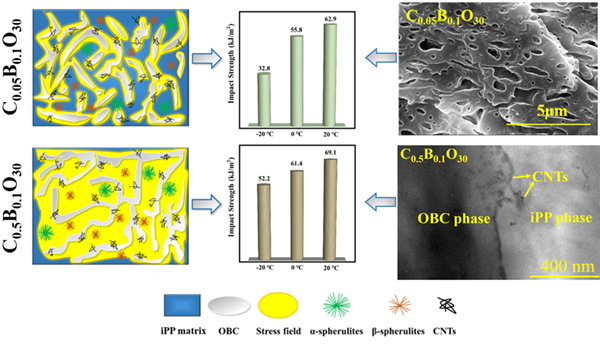

等規聚丙烯(iPP)是一種常用的熱塑性工程塑料材料,在過去的幾十年里被廣泛的用來制造購物袋、管材、農用薄膜以及其他的工業應用。然而,隨著使用溫度的降低,會極大地影響聚丙烯的韌性,會導致其由韌性到脆性的轉變,造成聚丙烯復合材料力學性能的惡化,這也大大的限制了聚丙烯管材在極端寒冷環境下的進一步應用。課題組針對聚丙烯耐寒問題,通過對聚丙烯復合材料內部微結構的調控,使iPP/0.1wt% β-NAs/30 wt% OBC共混體系具有超高的低溫沖擊韌性。與純iPP相比,在僅添加0.5wt% CNTs時,可使iPP/0.1wt% β-NAs/30 wt% OBC復合材料在使用溫度為-20℃時,低溫沖擊韌性高達52.2kJ/m2,其中沖擊強度增加幅度約2386%。通過CNTs添加含量的調控可使β-iPP復合材料形成共連續的相形態,這是復合材料在低溫環境下能顯著增強應力消散的關鍵。此外,CNTs在iPP和OBC相之間的分布以及β-NAs和OBC誘導的自增韌β-晶體的存在將有助于進一步提高iPP基復合材料的低溫沖擊強度。本課題組提出了一種切實可行的增強復合材料低溫韌性的策略,擴大了其在工業領域的應用潛力。

Isotactic polypropylene (iPP), as a common engineering thermoplastic material, is widely selected to manufacture shopping bag, pipe, agricultural film and other industrial applications inpast decades. However, decreasing the using temperature can induce thetransition from ductile to brittle failure of iPP, thereby inducing the dramatic deterioration of mechanical properties. Therefore, the poor low-temperature impact strength of iPP (especially below glass transition temperature, Tg) largely restricts its further applications in frigid environment such as outdoor pipelines. To broaden the potential application of isotactic polypropylene (iPP) in low-temperature conditions, iPP/0.1 wt% β-nucleated agent/30 wt% ethylene-octene multiblock copolymer (iPP/0.1 wt% β-NAs/30 wt% OBC) blends were endowed with ultrahigh low-temperature impact toughness by adjusting the nanotubes (CNTs) content. In comparison with pure iPP, the low-temperature impact toughness of iPP/0.1 wt% β-NAs/30 wt% OBC composites with only adding 0.5 wt% CNTs reached as high as 52.2 kJ/m2 at -20 ℃, of which the increment of impact strength was about 2386%. This optimum content of CNTs gave rise to a co-continuous phase morphology in β-nucleated iPP composites which turned out to be the key to the greatly enhanced stress dissipation, even at low-temperature environment. In addition, the distribution of CNTs between iPP and OBC phase, and the presence of self-toughened β-crystals that were induced by β-NAs and OBC contributed to improving the low-temperature impact strength of iPP-based composites. A feasible strategy is developed to substantially reinforce the low-temperature toughness of iPP-based composites, which expands their potential applications in industrial sectors.