Lin Tang, Junliang Zhang, Chunliang Wu, Yusheng Tang*, Hao Ma, Jie Kong and Junwei Gu*. UV etched random copolymer membrane coated PBO fibers/cyanate ester wave-trasnparent laminated composites. Composites Part B-Engineering, 2021, 212: 108680. 2019IF=7.635.(1區(qū)材料科學(xué)Top期刊)

(https://doi.org/10.1016/j.compositesb.2021.108680)

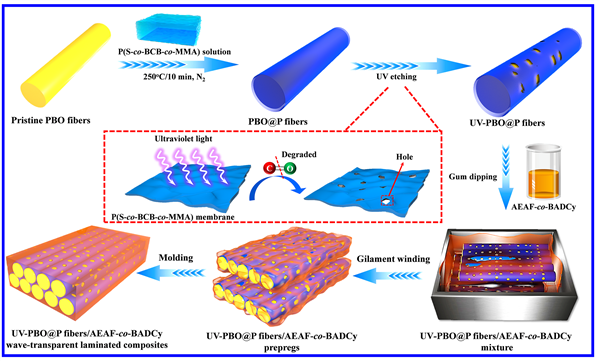

AbstractPoly(p-phenylene-2,6-benzobisoxazole) fibers treated by random copolymer P(S-co-BCB-co-MMA) membrane and UV etching (UV-PBO@P fibers) are performed as reinforcement, bisphenol AF/amantadine modified bisphenol A cyanate ester (AEAF-co-BADCy) resin as polymeric matrix, and the UV-PBO@P fibers/AEAF-co-BADCy wave-transparent laminated composites were then fabricated. When the P(S-co-BCB-co-MMA) membrane thickness is 62.3 nm and the UV etching time is 96 hrs, UV-PBO@P fibers display the best interfacial compatibility with AEAF-co-BADCy resin, and the corresponding wave-transparent laminated composites present the optimal comprehensive performance. Interlaminar shear strength (ILSS) and flexural strength are 50.2 and 745.6 MPa, 27.4% and 21.6% higher than those (ILSS of 39.4 MPa, flexural strength of 613.3 MPa) of pristine PBO fibers/AEAF-co-BADCy wave-transparent laminated composites, respectively. And the composites possess low complex permittivity and tanδ, corresponding |T|2 in the X band is 88.9~94.2%. High-frequency structural simulation (HFSS) results demonstrate that the radome from the composites displays high |T|2 of 89.1~93.1% in the X-band, close to the theoretical calculation value. This work provides a certain theoretical guidance for fabricating lightweight, high strength, and high |T|2 polymer matrix wave-transparent composites, and further broadens the application of PBO fibers and cyanate ester resins in aviation/aerospace, 5G communication services, electronic information, and other fields.

以無規(guī)共聚物P(S-co-BCB-co-MMA)膜和紫外刻蝕協(xié)同處理的聚對苯撐苯并二噁唑(PBO)纖維為增強(qiáng)體,雙酚AF/金剛烷改性的雙酚A氰酸酯(AEAF-co-BADCy)樹脂為透波基體,經(jīng)“浸漬-纏繞-鋪層-模壓”法制備UV-PBO@P纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料。結(jié)果表明,當(dāng)PBO纖維表面P(S-co-BCB-co-MMA)(分子量為32300)膜厚度為62.3 nm,且紫外刻蝕時(shí)間為96 hrs時(shí),UV96-PBO@P纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料具有最佳的力學(xué)性能、透波性能和熱性能。UV96-PBO@P纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料的層間剪切強(qiáng)度ILSS和彎曲強(qiáng)度分別為50.2 MPa和745.6 MPa,較純PBO纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料的ILSS(39.4 MPa)和彎曲強(qiáng)度(613.3 MPa)分別提高了27.4%和21.6%。復(fù)介電常數(shù)實(shí)部(εr'')、虛部(εr'''')和介電損耗角正切值(tanδ)分別為2.63、0.015和0.0057(10 GHz),且在X波段對應(yīng)的透波率為88.9~94.2%,明顯高于純PBO纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料對應(yīng)波段的透波率(83.4~90.8%);高頻結(jié)構(gòu)仿真(HFSS)模擬結(jié)果表明UV96-PBO@P纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料天線罩在整個(gè)X波段的透波率為89.1~93.1%,與理論計(jì)算的結(jié)果相近。同時(shí),UV96-PBO@P纖維/AEAF-co-BADCy樹脂層壓復(fù)合材料具有最高的耐熱指數(shù)(THRI,222.0oC)和玻璃化轉(zhuǎn)變溫度(Tg,236.3oC)。本工作可為制備輕質(zhì)、高強(qiáng)和高透波的樹脂基復(fù)合材料提供了一定的理論指導(dǎo),進(jìn)一步拓寬PBO纖維和氰酸酯樹脂在航空/航天、5G通訊服務(wù)、電子信息等領(lǐng)域的應(yīng)用范圍。