原文信息:

Expanded graphite (EG)/Ni@Melamine foam (MF)/EG sandwich-structured flexible bipolar plate with excellent electrical conductivity, mechanical properties, and gas permeability

原文鏈接:https://doi.org/10.1016/j.apenergy.2023.120929IF: 11.446 Q1

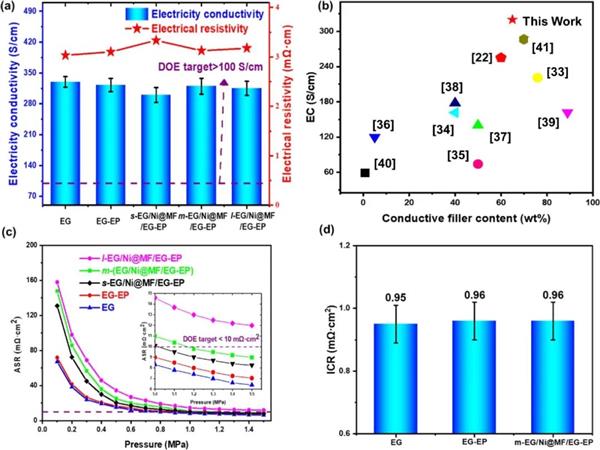

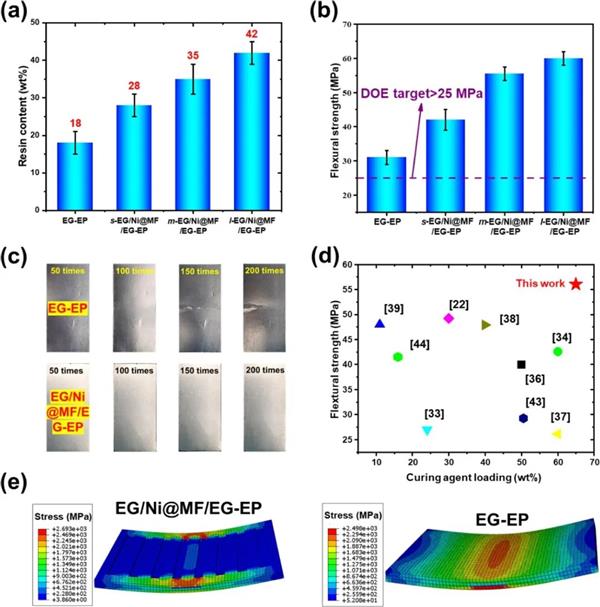

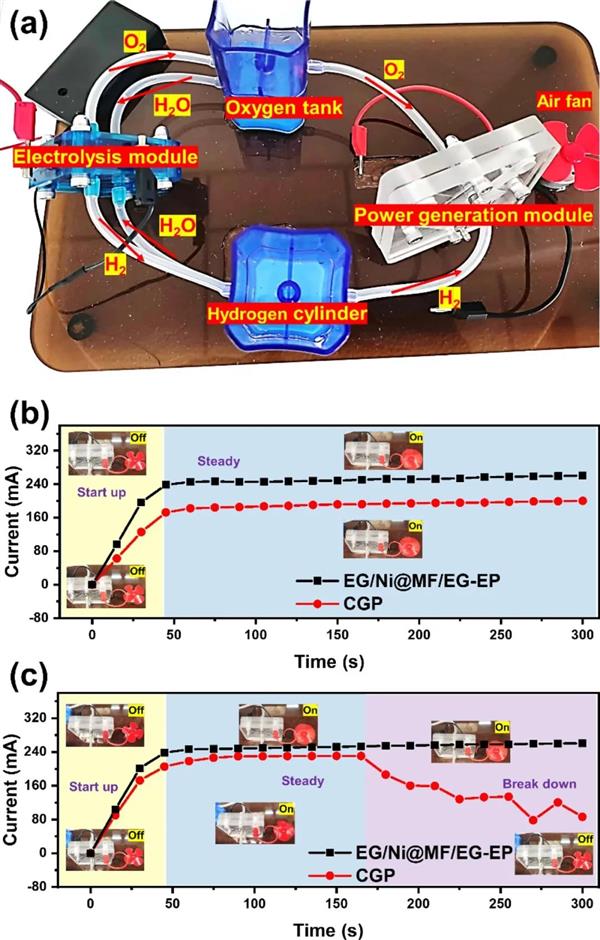

在這項工作中,作者提出了一種將膨脹石墨(EG)與鍍鎳三聚氰胺泡沫(Ni@MF)層壓與真空浸漬制備相結合的制備策略,制備了具有膨脹石墨(EG)/鍍鎳三聚氰胺泡沫(Ni@MF)夾層結構的復合雙極板。光滑的三聚氰胺泡沫表面完全覆蓋了鎳元素,提供了豐富的導電通路,電導率達到了320 S/cm,面積比電阻為9 mΩ·cm2。而多孔的三聚氰胺泡沫(MF)為浸漬環氧樹脂提供了足夠的空間,抗彎曲強度達到56 MPa。中間層的富集樹脂量也保證了較低的透氣性(2.16×10-9 cm3cm-2s-1)。此外,經過表面處理的復合板表面也具有較好的疏水性能,達到90.2°。進一步的實際性能試驗證明,與商業化的碳化石墨板相比,所研制的板在實際工況下具有良好的性能。該復合雙極板將新型結構的創新和制備技術的結合也是燃料電池復合雙極板獲得高電導率,高機械性能和低氣體滲透性的關鍵。

Fig. 1. (a) Schematic diagram for the syntheses of Ni@MF; (b) preparation process of EG/Ni@MF/EG-EP composite bipolar plate.

Fig. 2. (a) EC and ER of EG, EG-EP, and EG/Ni@MF/EG-EP plates; (b) Comparison of the EC of the m-EG/Ni@MF/EG-EP plate in this work with other reported work; (c) ASR of EG, EG-EP, and EG/Ni@MF/EG-EP plates; (d) ICR of EG, EG-EP, and m-EG/Ni@MF/EG-EP plates.

Fig. 3. (a) The maximum resin content that can be immersed in the plates; (b) flexural strength of the plates; (c) comparison of actual bending fatigue tests between EG and EG/Ni@MF/EG-EP plates; (d) mechanical behavior of the developed plate in this work with other reported work; (e) stress condition comparison of the EG/Ni@MF/EG-EP composite plate and EG-EP plate obtained by FEM simulation.

Fig. 4. (a) Schematic of the designed demo system of a single fuel cell; (b) comparison of the current change with time between the EG/Ni@MF/EG plate and CGP; (c) comparison of the current change with time between the EG/Ni@MF/EG plate and CGP under external shaking.