Improving the mechanical properties and flame retardancy of ethylene-vinyl acetate copolymer by introducing bis [3-(triethoxysilyl) propyl] tetrasulfide modified magnesium hydroxide

writer:張勝,卜祥星,谷曉昱*,孫軍,李洪飛,唐武飛

keywords:ethylene-vinyl acetate copolymer, magnesium hydroxide, bis [3-(triethoxysilyl) propyl] tetrasulfide, surface modification, flame retardancy

source:期刊

specific source:Surface and Interface Analysis

Issue time:2017年

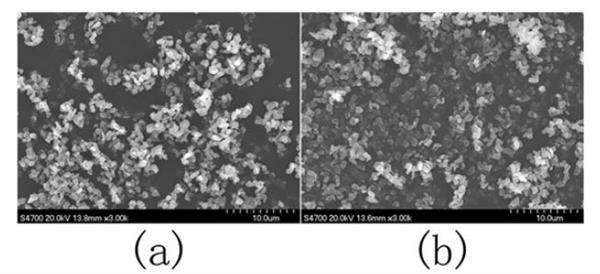

Magnesium hydroxide (MH) was surface modified by bis [3-(triethoxysilyl) propyl] tetrasulfide (Si-69) in order to improve its compatibility with ethylene-vinyl acetate (EVA) copolymer substrate. The modified MH (SMH) was then introduced to EVA through melt blending. The flammability was evaluated by limiting oxygen index (LOI), vertical burning test and cone calorimeter; 40wt% MH/SMH will lift LOI from 17.9 in EVA to 22.3/23.3, respectively. In cone test, the peak heat release rate (PHRR) of EVA is 1382kW/m(2) and reduced sharply to 601/489kW/m(2) for 40wt% MH/SMH adding, respectively. The mechanical properties were tested by a drawing machine. The elongation at break dropped almost 7 times by the addition of 40wt% MH, from 825% in EVA dived to 124%, whereas up to 745% by the addition of 40wt% SMH. The morphology observation by scanning electron microscopy (SEM) indicated the dispersion of surface modified MH in EVA was remarkably improved than that of MH.